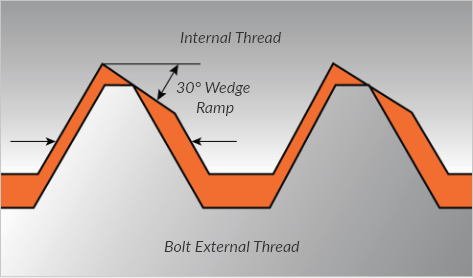

The EMUGE Self-Lock™ locking feature is integrated into the internal profile and works without any additional mechanical or chemical locking devices, therefore temperature variations do not noticeably affect it. A modification to the standard thread profile, in the form of a 30-degree wedge ramp surface on the major diameter produces the locking effect. Since the bolt thread is not affected in any way, standard bolts of tolerance class 2A or 6g can be used.

Self-Lock™ is an engineered wedge ramp at the root of the internal thread that only engages when the joint starts to build clamp load during tightening. At that point, the crest of the standard external threads draws tightly against the wedge ramp, eliminating all radial clearance and creating a continuous spiral line of contact between the internal and external threads.

Standard 60° Thread

Self-Lock™ Thread

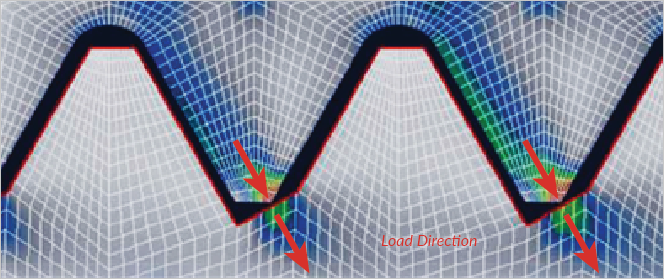

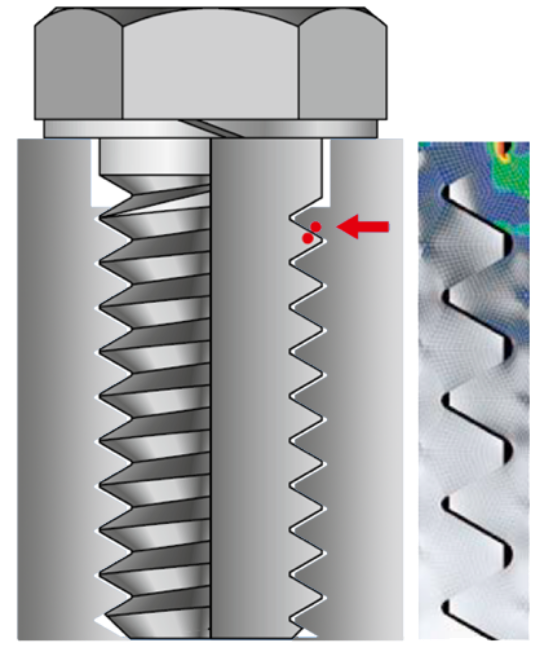

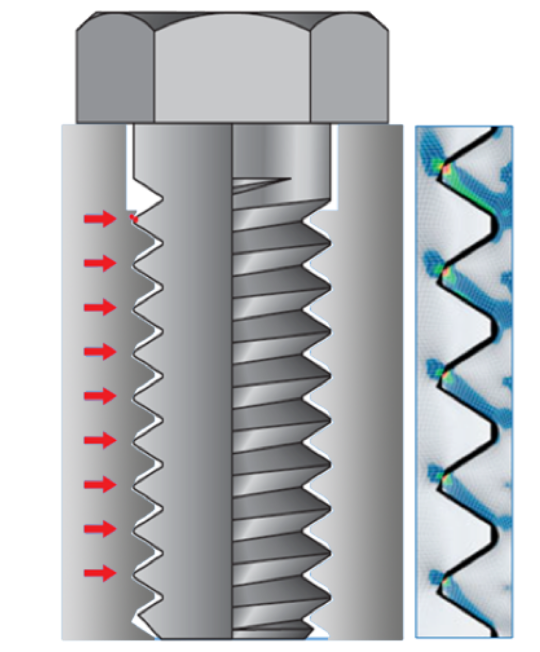

The first two threads on a conventional fastener (left) may carry as much as 75% of the load, while load on the other threads is drastically reduced. A standard 60-degree thread form leaves a radial gap between the crest of the male and female threads. This makes the nut-bolt assembly susceptible to transverse motion and loosening under vibrational loads. Additionally, when the first one or two threads carry most of the axial tension load, highly concentrated contact stresses can cause fatigue and the probability for shear and thread stripping, especially when bolts thread into soft metals. The EMUGE Self-Lock™ profile eliminates the radial gap and creates a continuous-spiral-line of contact along the whole thread engagement and more evenly distributes the concentration of tightening force. Calculations amount to a share of 17% of total load on the first thread and an amazing 12.5% even on the last engaged thread.

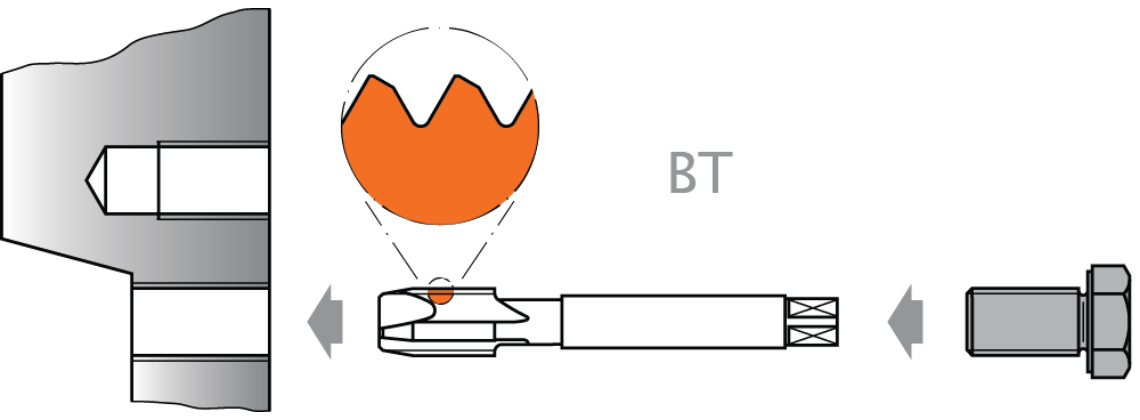

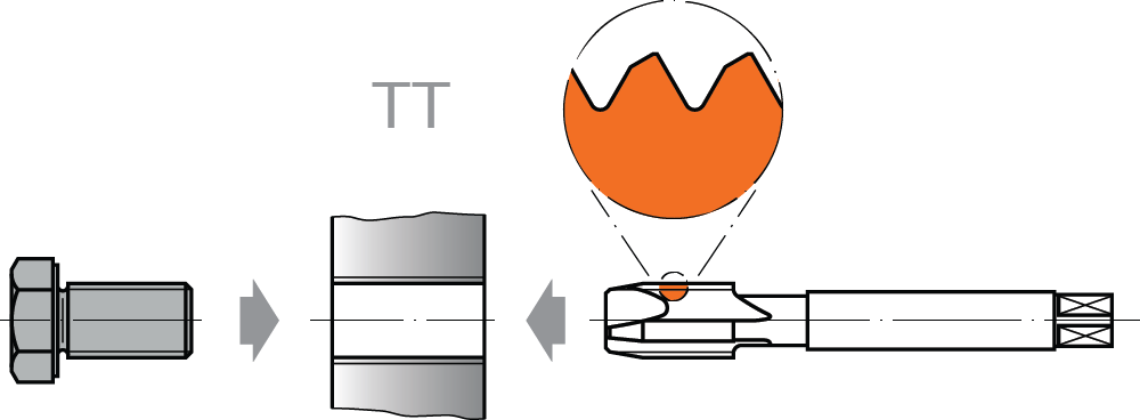

Because the thread consists of a fixed ramp angle, the direction of the threading process and the bolt insertion must be considered. The process is designated as BT (Back Taper) or TT (Top Taper).

Back Taper: Blind hole and thru hole with same screw-in and cutting direction

Top Taper: Thru hole with opposite screw-in to cutting direction

To avoid potential assembly problems due to dimensional variations, we highly recommend inspecting EMUGE Self-Lock™ threads exclusively with EMUGE Self-Lock™ gages to ensure the highest and most constant locking power. We recommend using an EMUGE two-piece gage system which corresponds to the normal combination of Go and No-Go. These gages are perfectly sufficient for the gaging of the EMUGE Self-Lock™ thread, provided that the Self- Lock threads were produced with a true-to-profile EMUGE tap.

Let our experts provide recommendations for your project or application.

EMUGE-FRANKEN USA is a wholly owned subsidiary of the 1,500+ employee German company EMUGE-Werk Richard Glimpel GmbH & Co. KG (Lauf, Germany). A product technology and performance leader for over 100 years, EMUGE-FRANKEN manufactures an extensive line of taps, thread mills, drills, end mills, toolholders, clamping devices, and other rotary cutting tools.

EMUGE-FRANKEN also offers end-user technical support through a network of in-the-field engineers and in-house product specialists, all with extensive tooling and application experience.

Additional services include tool and tool holder repair and reconditioning, test cut services and CNC programming assistance.