Webinars

60 MIN.

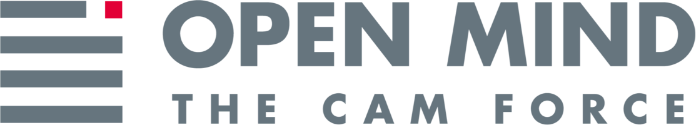

5 Tips for Avoiding the Dreaded Broken Tap

Join our special webinar led by industry veteran, Tom Kowalski from EMUGE-FRANKEN USA, who will share essential advice on how to minimize tap breakage. Learn, through five easy-to-follow guidelines, how to choose the correct tap for your application, ensuring fewer breaks and more reasons to smile!

In this educational session, Tom will delve into the importance of tap selection, drilling considerations, and crucial decision-making that EMUGE-FRANKEN employs to optimize thread quality and tool life – ultimately helping you avoid the dreaded broken tap!

Here is a sneak peek at what you will uncover in this webinar:

- The five critical questions that every engineer and machinist must address before selecting a tap, providing a roadmap to efficiently navigate the maze of options.

- Understanding the impact of tool holders on thread quality, tool longevity, and mastering the art of selecting the correct lubricant tailored to your specific application requirements.

- When to “Tap Out” and consider the shift towards thread milling, offering invaluable guidance on making this strategic transition seamlessly.

A Collaboration with:

30 MIN.

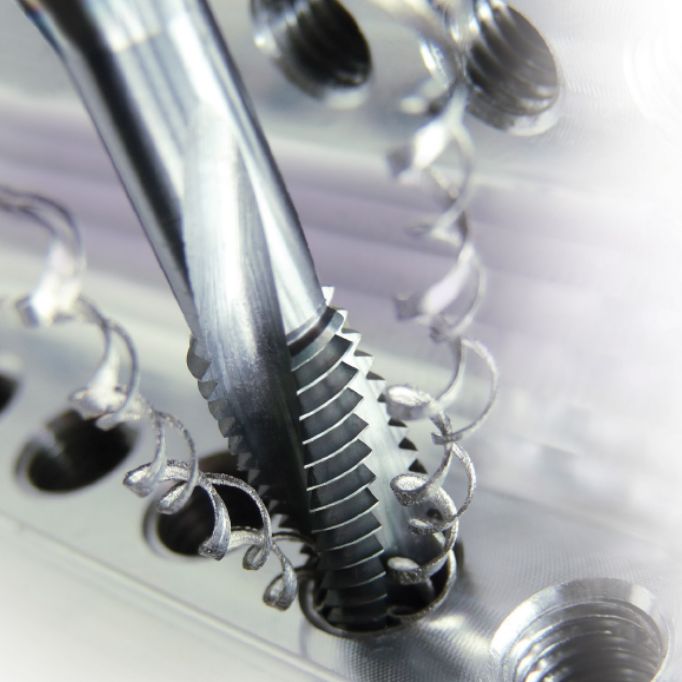

Strategies for Reducing Machining Time, Tools in Challenging 5-Axis Aerospace Parts

Complex part geometries and tough materials present milling challenges for aerospace manufacturers. Gaining an understanding of the milling tool options available, as well as strategies for applying them, is key for reducing tool consumption and optimizing 5-axis cycle times.

- The latest end mill technologies include ceramic end mills for the high-speed roughing and milling of heat resistant super alloys, producing high metal removal rates in challenging nickel-based alloys, and machining parts 200 to 400% faster than conventional carbide end mills.

- Circle Segment end mills feature unique design forms with large radii, allowing a much larger axial depth-of-cut during pre-finish and finishing in 5-axis applications, generating cycle time reductions of up to 90%.

- Options for cutting and polishing in one operation to produce mirror finishes in non-ferrous materials, saving significant time and costs will be reviewed. And, critical for application success, tips for selecting the optimal toolholder will be discussed.

A Collaboration with:

30 MIN.

How to Fit 12 Tools into a 10-Station Tool Change? The EMUGE Thriller Drill / Thread / Chamfer

It seems like no matter how many tools your ATC can fit, it never seems to be enough.

What if you could combine three tools into one? Introducing the EMUGE Thriller drill thread mill. This unique tool allows you to replace a tap drill, tap, and spot drill into one. Your first question would probably be: “How can I program that”?

Join Siemens's Mr. CNC, Chris Pollack, for a quick YouTube live session and see an interactive cutting demonstration that answers this question by taking advantage of the SINUMERIK CNC’s standard cycle that supports some amazing tools.

And for you guys that may not have moved to the Siemens control yet, no worries. We’ll also look at how to handle an application like this with basic cycle.

A Collaboration with:

30 MIN.

Tapping Titanium with EMUGE-FRANKEN & Tapmatic

- Winning strategies for meeting the unique challenges of putting screw threads in titanium.

- Learn how to avoid common threading problems related to tapping titanium and optimize tap life.

- Select the correct tap and tap holder – and determine when a thread mill is a better option.

A Collaboration with:

30 MIN.

Thread Production for Challenging, Safety-Critical Aerospace Parts

Complex materials such as Inconel, nickel-based superalloys, Monel, titanium, 420 stainless steel, and more are increasingly being used in aerospace part manufacture. Threading these tough materials can pose challenges, so having the right thread mills for the job is key to success.

A Collaboration with:

30 MIN.

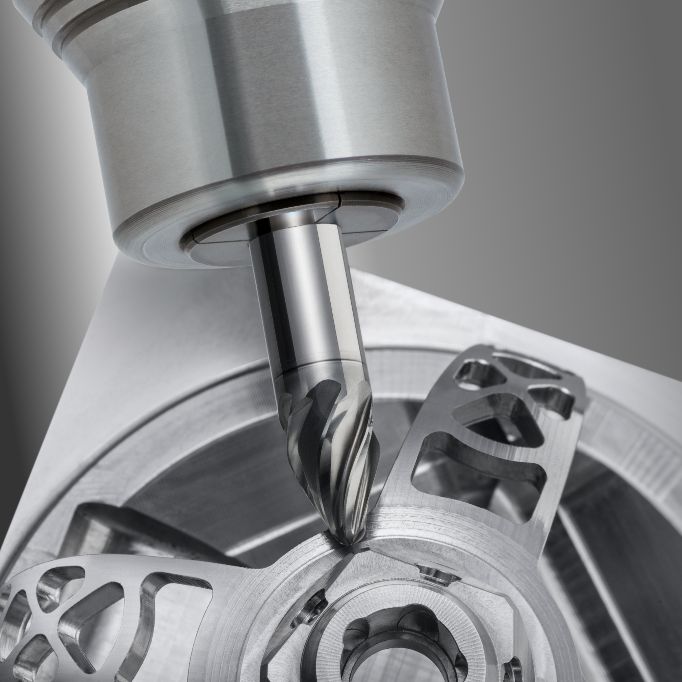

A Closer Look At 5-Axis Machining with Circle Segment End Mills

Reducing cycle times and achieving a superior surface finish are two key goals when 5-Axis machining. Manufacturers in aerospace, medical and automotive, die/ mold, and many other industries that machine parts traditionally with a ball nose end mill have access to a powerful alternative: Circle Segment End Mills (also known as Conical Barrel Cutters). Increased tool life, superb finishes, and significantly reduced cycle times are all easily achieved when using Circle Segment End Mills. Attend this session to gain a solid understanding of this highly productive milling option including the following overview: Circle Segment Tools Defined Tool Types and Applications CAM Software Requirement Why Choose Circle Segment over Ball Mills or Conventional Finishing Strategies (and when not to) Real-Life Application Examples SPEAKER: Evan Duncanson, Milling Applications Specialist, EMUGE-FRANKEN USA

45 MIN.

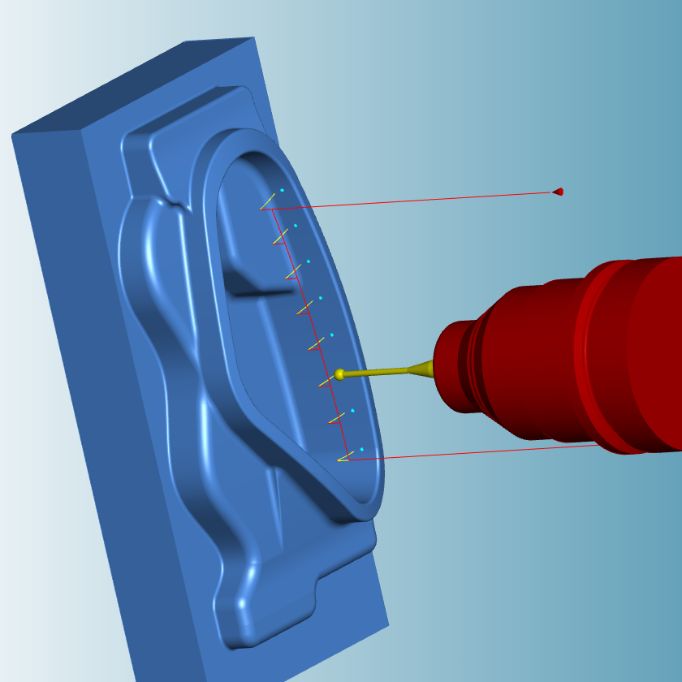

Enhancing Accuracy in Mold & Die Applications

This webinar covers:

- Achieving high-quality surface finishes with hyperMILL’s high precision surface mode by machining directly to the surface instead of an “approximated mesh” and applying the CAM software’s smooth overlap capability which minimizes witness marks at the blending of adjoining part features.

- Utilizing the GROB G550a 5-Axis capabilities to properly orient and consistently maintain the EMUGE-FRANKEN Multi-Cut Duplex End Mill in the cut, while extending tool life.

- Strategies for maximizing the efficiency of the machining process with hyperMILL’s auto-indexing function to automatically generate multiple 3+2 segments as an alternative to 5-Axis.

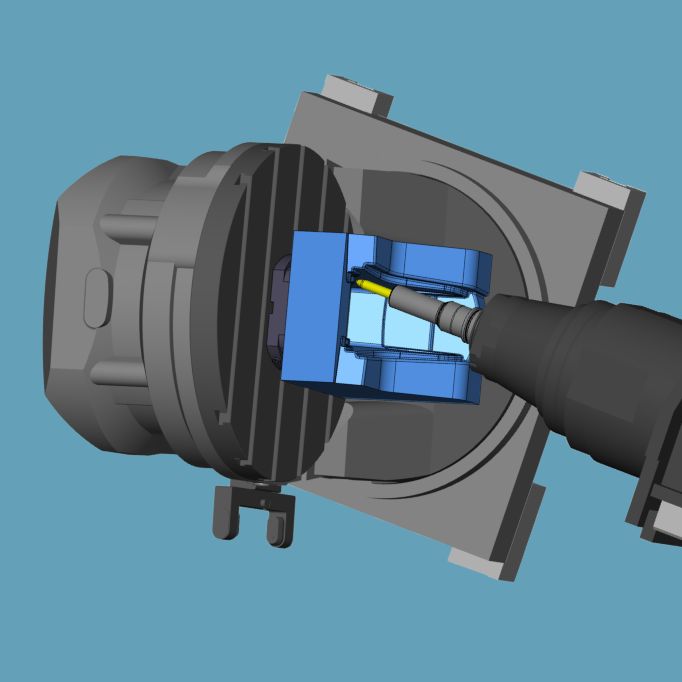

- How to use shorter, smaller diameter tools for more aggressive machining by combining GROB’s rigid cross-slide design and long Z-Axis stroke with hyperMILL’s 5-Axis rest machining strategy, and EMUGE’s rigid FPC tool holder.

- Tips for optimizing the workflow within multiple application stages by using process probing strategies.

45 MIN.

Deep Cavity and Gun Drill Machining

This workshop presents a collaboration of GROB Systems, OPEN MIND Technologies, and EMUGE-FRANKEN for the demonstration of deep cavity and gun drilling applications. During this event, GROB’s 400mm pallet, horizontal 5-axis machining center, the G350, will demonstrate how difficult deep cavity and gun drilling applications can be made easily with GROB’s unique machine kinematics. OPEN MIND will highlight the application of conical barrel (Circle Segment) cutters for effective surface finishing, in-process probing, and our innovative deep hole drilling processes. EMUGE-FRANKEN will showcase Circle Segment cutters and FPC milling holders for high-performance machining.