These tools are primarily used in mold-making as well as in the production of tire molds, turbine blades, impeller blades, or blisks. Circle Segment end mills can optimize any 5-axis milling application with reduced cycle times and improved surface finishes.

Download the free product guide. This comprehensive product guide provides details and specifications about EMUGE-FRANKEN Circle Segment and Turbine End Mills - both exceptional milling strategies for aerospace, mold and die, medical, turbine machining, and more.

Included in the Guide:

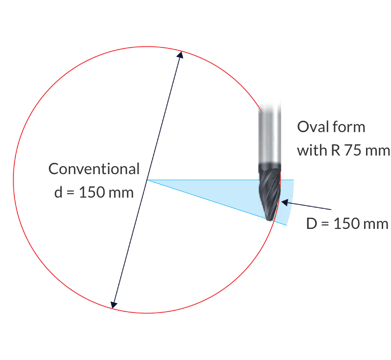

What makes these end mills unique is the large radii in the cutting area of the respective tool which offer entirely new possibilities in machining. The large radius simulates a ball-nose end mill with a cutting diameter of 12 to 3000 mm and even larger on request.

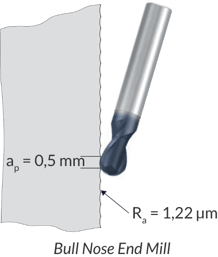

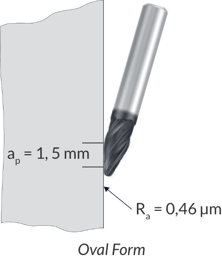

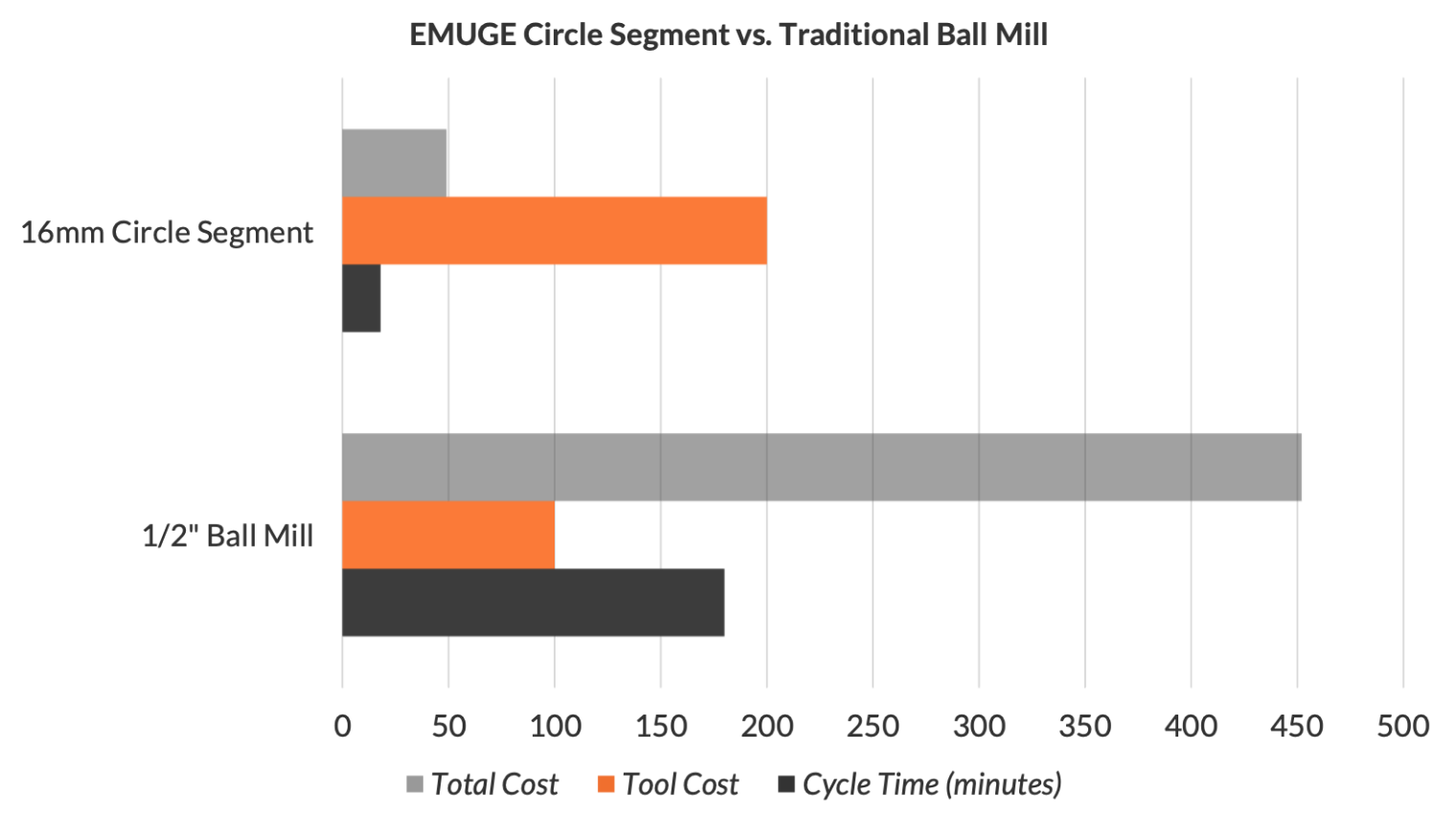

EMUGE-FRANKEN tooling design engineers worked closely with the industry leaders in CAM software to develop milling cutters that would optimize the performance of their software’s capabilities to produce complex shapes with superior surface finishes. By combining advanced cutting-edge geometries with exaggerated radius profiles, Circle Segment end mills mimic large diameter cutter profiles with standard tooling sizes. For example, a 16 mm diameter end mill can produce a 500 mm radius profile in one pass. This significantly increases the step over width of the end mill and reduces the milling cycle time by up to 90%.

The ability to increase step over width drives down cycle time and improve surface finishes. Turbine blade milling results that were unachievable in the past are now being realized with this new technology.

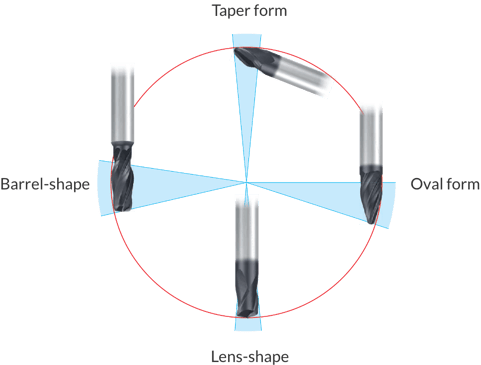

The Circle Segment family of tools include the following options.

Let our team of experts provide recommendations for your project or application.

EMUGE-FRANKEN USA is a wholly owned subsidiary of the 1,500+ employee German company EMUGE-Werk Richard Glimpel GmbH & Co. KG (Lauf, Germany). A product technology and performance leader for over 100 years, EMUGE-FRANKEN manufactures an extensive line of taps, thread mills, drills, end mills, toolholders, clamping devices, and other rotary cutting tools.

EMUGE-FRANKEN also offers end-user technical support through a network of in-the-field engineers and in-house product specialists, all with extensive tooling and application experience.

Additional services include tool and tool holder repair and reconditioning, test cut services and CNC programming assistance.